- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Sinae Tantalum Carbide Coating fabrica, supplementum, Factory

VeTek semiconductor est primarius fabricae Tantali Carbide Coating materias semiconductoris industriae. Nostrae oblationes principales productae includunt partes CVD tantalum carbidam coating partes, sintedi TaC partes efficiens pro cristallo augmenti SiC vel epitaxiae semiconductoris. Transierunt ISO9001, VeTek Semiconductor bonam potestatem in qualitate habet. VeTek Semiconductor dicatus est ut innovator factus sit in Tantalum Carbide Coating industriam per permanentem inquisitionem et progressionem technologiarum iterativarum.

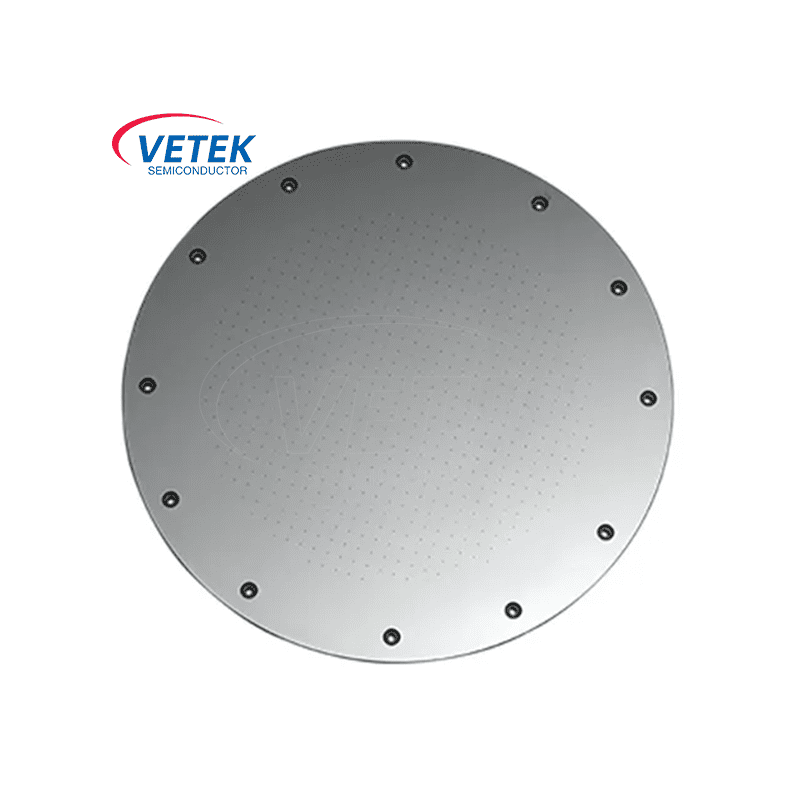

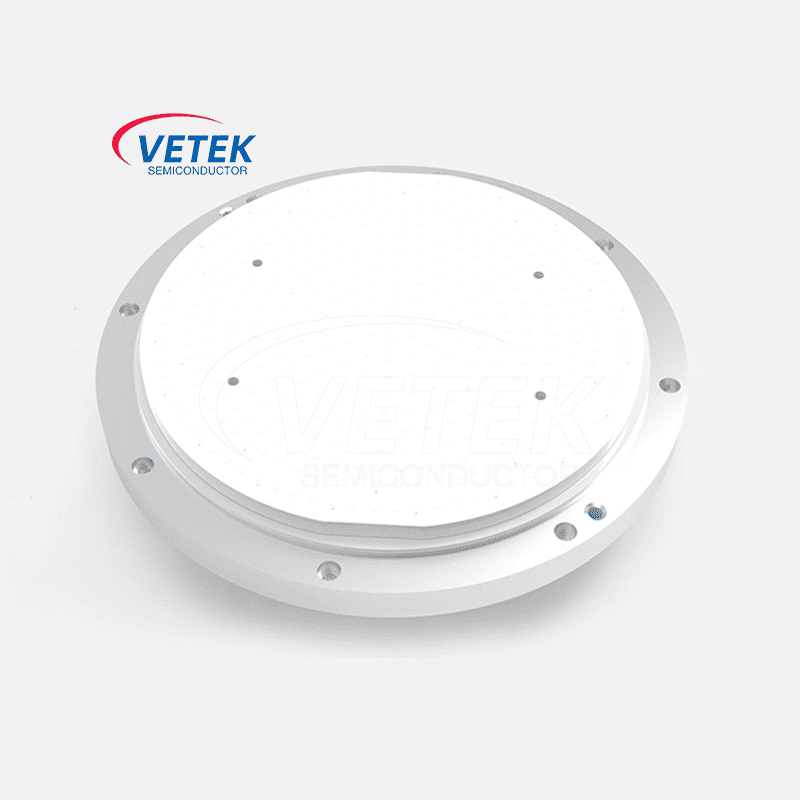

Pelagus products suntTantalum Carbide vestiens defector anulus, TaC obductis diuersionis anulus, TaC dimidiatae partes lunae, Tantalum Carbide Coated rotationis Orbis Planetariae (Aixtron G10), TaC Crucible Coated; TaC Coated Annulos; TaC Coated Porous Graphite; Tantalum Carbide Coating Graphite Susceptor; TaC Coated Guide Ring; TaC Tantalum Carbide Coated Plate; TaC Coated Wafer Susceptor; TaC Coating Ring; TaC Coating Graphite Cover; TaC Coated Chunketc., puritas est infra 5ppm, occurrere mos requisitis.

TaC graphite coating creatum est superficies graphitae altae puritatis substratae cum strato subtilissimo carbidi tantali per Depositionis Vaporis chemici proprietatis (CVD) processum. Commodum infra picturam ostenditur:

Tantalum carbide (TaC) efficiens attentionem consecuta est ob altitudinem eius liquescentis punctum usque ad 3880°C, excellentem roboris mechanicam, duritiem et resistentiam ad pulsuum thermarum, idque amabili modo ad compositiones semiconductoris epitaxy processuum cum temperatura superiori requisitis; ut Aixtron MOCVD systema et LPE SiC processum epitaxy. Etiam late patet in PVT methodo SiC processum cristallinum.

Key Features:

●Temperatus stabilitas

●Ultra alta munditia

●Resistentia ad H2, NH3, SiH4, Si

●Resistentia ad scelerisque stirpe

●Fortis adhaesio graphite

●Conformal coating coverage

● Magnitudo usque ad 750 mm diameter (Sola fabrica in Sinis hanc magnitudinem attingit)

Applications:

calefactio inductiva susceptor

calefactio elementum resistens

Calor scutum

Tantalum carbide (TaC) efficiens microscopic cross-sectioni:

Parameter VeTek Semiconductor Tantalum Carbide Coating:

| Corporalis proprietatibus TaC coating | |

| Density | 14.3 (g/cm³) |

| Imprimis emissivity | 0.3 |

| Scelerisque expansion coefficientes | 6.3 10-6/K |

| Duritia (HK) | 2000 HK |

| Resistentia | 1×10-5Ohm* cm |

| Scelerisque status | <2500℃ |

| Graphite magnitudine mutationes | -10~-20um |

| Crassitudo coating | ≥20um valorem typicum (35um±10um) |

TaC coating EDX data:

TaC efficiens crystal structuram data:

| Elementum | Cento atomicus | |||

| Pt. 1 | Pt. 2 | Pt. 3 | Mediocris | |

| C K | 52.10 | 57.41 | 52.37 | 53.96 |

| The M | 47.90 | 42.59 | 47.63 | 46.04 |

- View as