- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Sinae Tantalum Carbide Coating fabrica, supplementum, Factory

VeTek semiconductor est primarius fabricae Tantali Carbide Coating materias semiconductoris industriae. Nostrae oblationes principales productae includunt partes CVD tantalum carbidam coating partes, sintedi TaC partes efficiens pro cristallo augmenti SiC vel epitaxiae semiconductoris. Transierunt ISO9001, VeTek Semiconductor bonam potestatem in qualitate habet. VeTek Semiconductor dicatus est ut innovator factus sit in Tantalum Carbide Coating industriam per permanentem inquisitionem et progressionem technologiarum iterativarum.

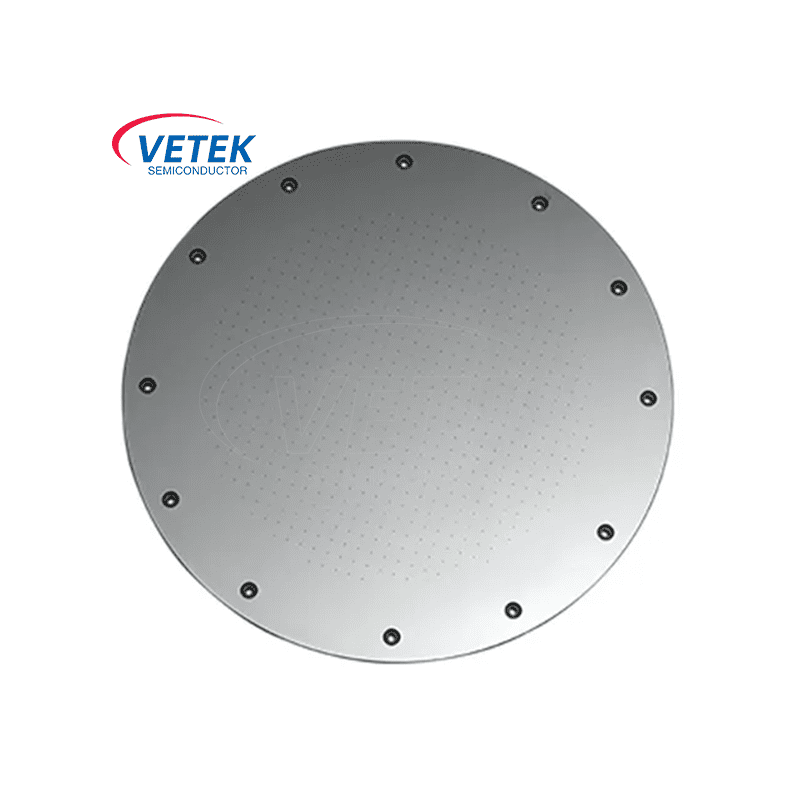

Pelagus products suntTantalum Carbide vestiens defector anulus, TaC obductis diuersionis anulus, TaC dimidiatae partes lunae, Tantalum Carbide Coated rotationis Orbis Planetariae (Aixtron G10), TaC Crucible Coated; TaC Coated Annulos; TaC Coated Porous Graphite; Tantalum Carbide Coating Graphite Susceptor; TaC Coated Guide Ring; TaC Tantalum Carbide Coated Plate; TaC Coated Wafer Susceptor; TaC Coating Ring; TaC Coating Graphite Cover; TaC Coated Chunketc., puritas est infra 5ppm, occurrere mos requisitis.

TaC graphite coating creatum est superficies graphitae altae puritatis substratae cum strato subtilissimo carbidi tantali per Depositionis Vaporis chemici proprietatis (CVD) processum. Commodum infra picturam ostenditur:

Tantalum carbide (TaC) efficiens attentionem consecuta est ob altitudinem eius liquescentis punctum usque ad 3880°C, excellentem roboris mechanicam, duritiem et resistentiam ad pulsuum thermarum, idque amabili modo ad compositiones semiconductoris epitaxy processuum cum temperatura superiori requisitis; ut Aixtron MOCVD systema et LPE SiC processum epitaxy. Etiam late patet in PVT methodo SiC processum cristallinum.

Key Features:

●Temperatus stabilitas

●Ultra alta munditia

●Resistentia ad H2, NH3, SiH4, Si

●Resistentia ad scelerisque stirpe

●Fortis adhaesio graphite

●Conformal coating coverage

● Magnitudo usque ad 750 mm diameter (Sola fabrica in Sinis hanc magnitudinem attingit)

Applications:

calefactio inductiva susceptor

calefactio elementum resistens

Calor scutum

Tantalum carbide (TaC) efficiens microscopic cross-sectioni:

Parameter VeTek Semiconductor Tantalum Carbide Coating:

| Corporalis proprietatibus TaC coating | |

| Density | 14.3 (g/cm³) |

| Imprimis emissivity | 0.3 |

| Scelerisque expansion coefficientes | 6.3 10-6/K |

| Duritia (HK) | 2000 HK |

| Resistentia | 1×10-5Ohm* cm |

| Scelerisque status | <2500℃ |

| Graphite magnitudine mutationes | -10~-20um |

| Crassitudo coating | ≥20um valorem typicum (35um±10um) |

TaC coating EDX data:

TaC efficiens crystal structuram data:

| Elementum | Cento atomicus | |||

| Pt. 1 | Pt. 2 | Pt. 3 | Mediocris | |

| C K | 52.10 | 57.41 | 52.37 | 53.96 |

| The M | 47.90 | 42.59 | 47.63 | 46.04 |

- View as

TaC Coating Parce Part

VeTek Semiconductor est fabrica professionalis Plate TaC Coating et aliae TaC Coating partes parce in Sinis. TaC Coating principaliter adhibetur in processibus sicut carbide siliconis unius cristalli incrementi (PVT methodi), disci epitaxialis (inclusa epitaxia carbide pii, epitaxia LED), etc. Composita cum bono diuturno stabilitatis Tabulae TaC Coating, VeTek Semiconductoris TaC. Plate Coing facta est Probatio partium parcentium TaC Coing. Expectamus te diuturnum nostrum socium fieri.

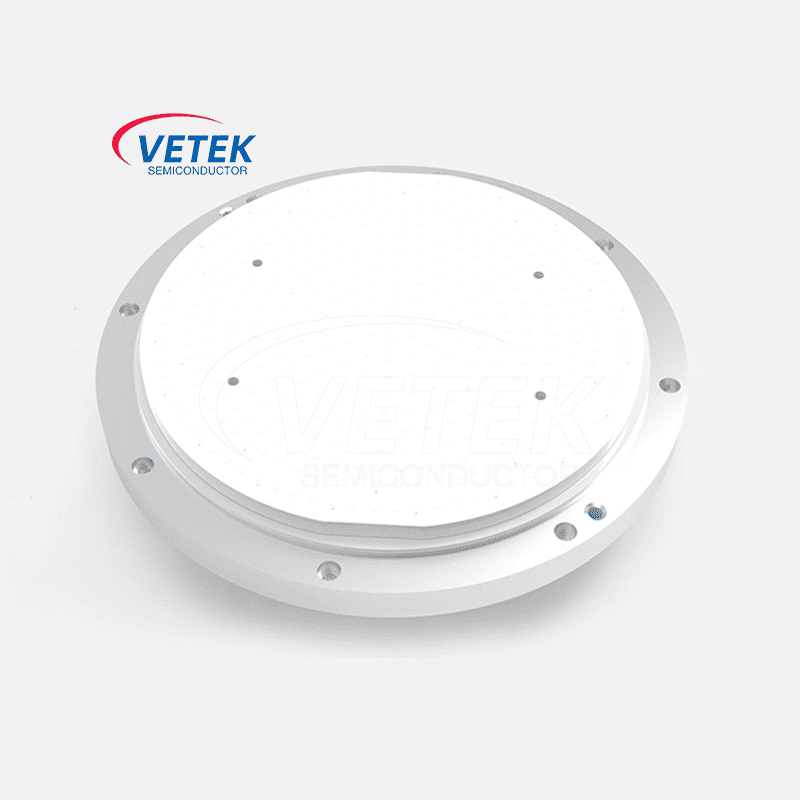

Lege plusMitte InquisitionemGaN on SiC epi susceptor

VeTek Semiconductor est fabrica professionalis GaN in SiC epi susceptoris, CVD SiC tunica, et CVD TAC COATING susceptoris graphitici in Sinis. Inter eos, GaN in SiC epi susceptor munere funguntur vitalis in processu semiconductoris. Per suam optimam scelerisque conductivity, caliditas processus capacitatis et stabilitatis chemicae, altam efficientiam et qualitatem materialem progressionis incrementi GaN epitaxialis efficit. Sincere nos expectamus ulteriorem consultationem tuam.

Lege plusMitte InquisitionemCVD TaC Coating Portitorem

VeTek tabellarius semiconductoris CVD TaC Coating maxime designatus est ad processum epitaxialem semiconductoris fabricandi. CVD TaC Coating tabellarius's Ultra-high tabescentibus punctum, egregium corrosio resistentiae, et praestantia stabilitatis scelerisque determinant indispensabilitatem huius operis in processu epitaxiali semiconductoris. Diuturnum negotium cum te condere sincere speramus.

Lege plusMitte InquisitionemTaC Coating Guide Ring

VeTek Semiconductoris TaC Coating Guide Ringe creatur applicando tantalum carbidam in partibus graphitis efficiens utens ars chemica depositio vaporum valde provectus dicta (CVD). Haec methodus bene stabilitur et eximias tunicas proprietates praebet. Adhibitis TaC Coating Guide Ringo, vitae graphitarum componentium signanter extendi potest, motus immunditiarum graphitarum supprimi potest, et SiC et AIN una qualitas crystalli certo conservari potest. Grata quaerenda nobis.

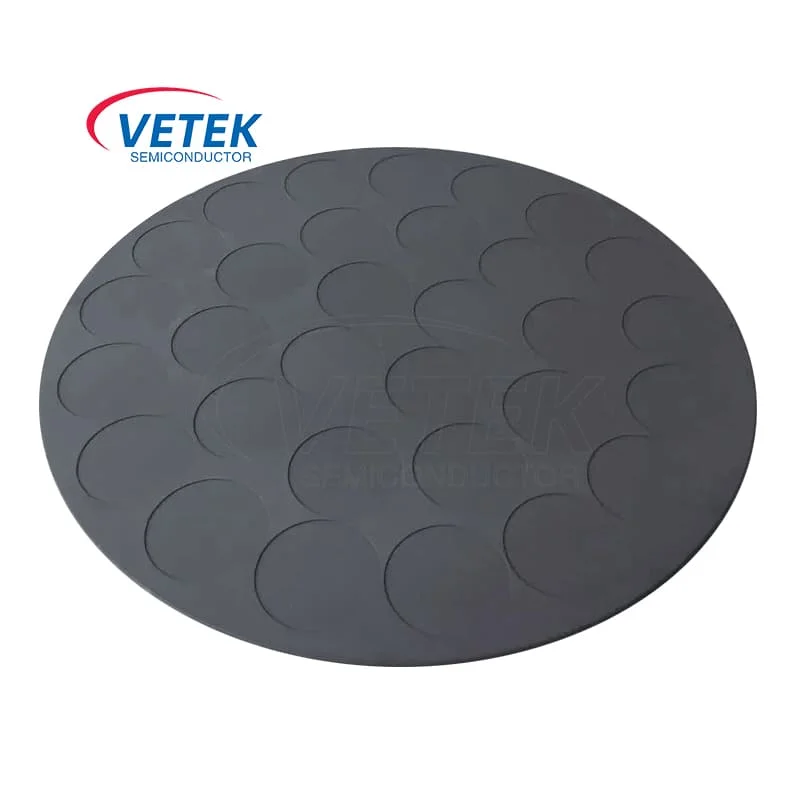

Lege plusMitte InquisitionemTaC Coated Graphite Susceptor

VeTek Semiconductoris TaC Coated Graphite Susceptor utitur depositione vaporum chemicorum (CVD) methodo parandi tantalum carbidum in superficie partium graphitarum efficiens. Hic processus est perfectissimus et optimus efficiens proprietates. TaC Coated Graphite Susceptor vitam graphitatam extendere potest, migrationem immunditiarum graphitarum inhibere, et epitaxiae qualitatem curare. VeTek Semiconductor inquisitionis tuae exspecto.

Lege plusMitte InquisitionemTaC Coating Susceptor

VeTek Semiconductor exhibet Susceptorem TaC Coating, Cum eximia TaC coating, susceptor hic praebet multitudinem commoda quae eam separant a solutionibus conventionalibus. Integrans compaginem in systemata exsistentia, TaC Coating Susceptorem de VeTek Semiconductor praestat convenientiam et operationem efficientem. Eius effectus certa et summus qualitas TaC efficiens constanter eximios exitus in processibus SiC epitaxy trades. Committitur nobis comparandis qualitas products pretiis competitive pretium et expectamus esse diuturnum tempus socium tuum in Sinis.

Lege plusMitte Inquisitionem