- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Silicon Carbide obductis Epi susceptor

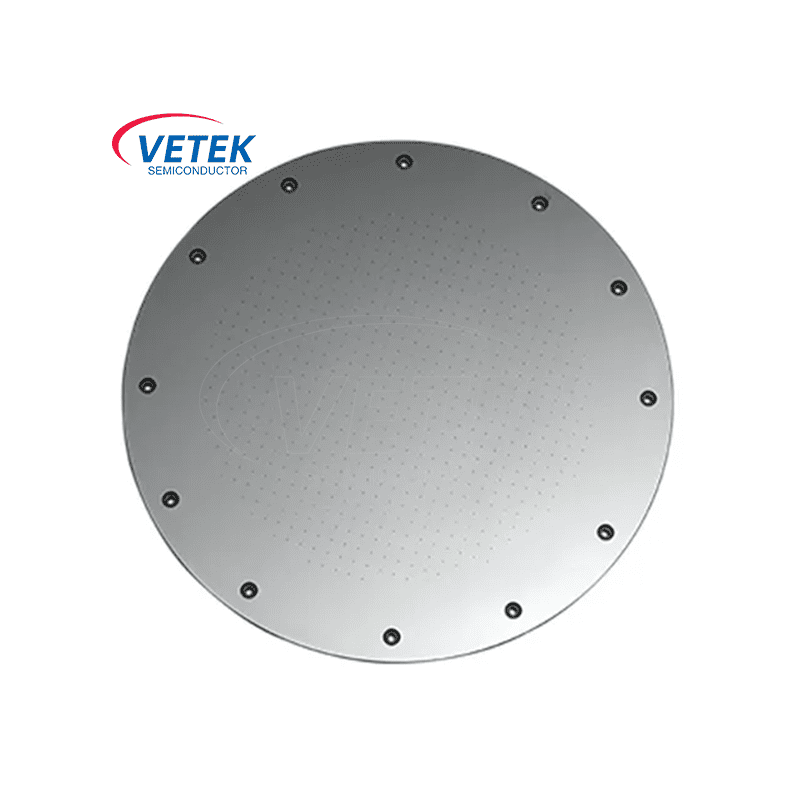

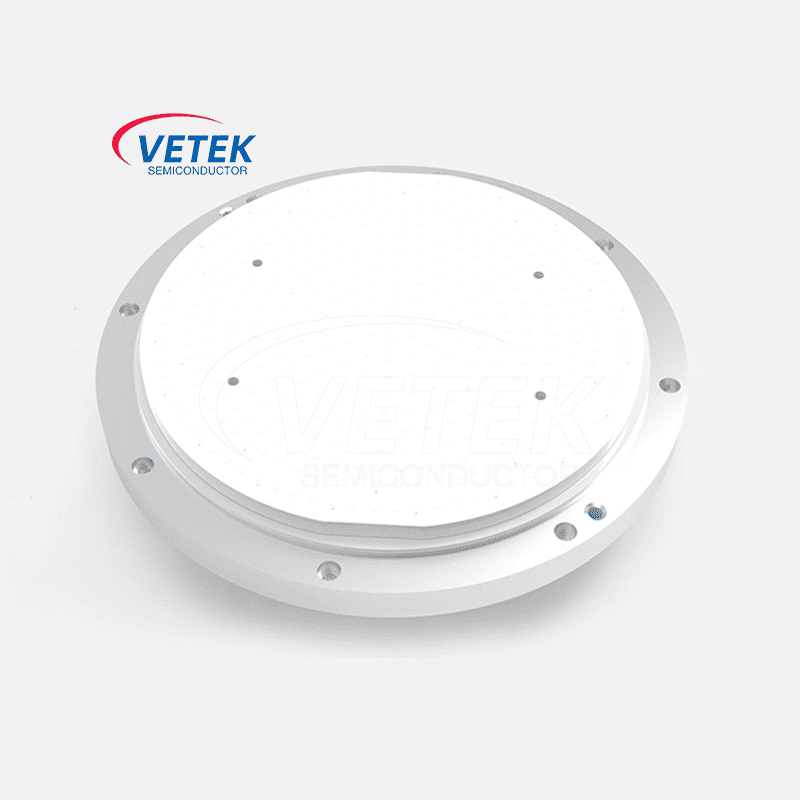

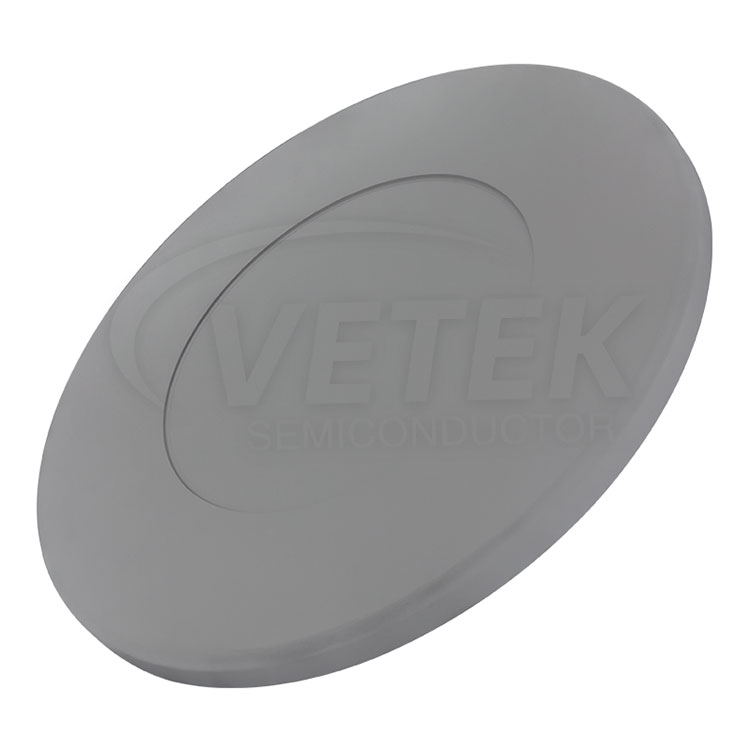

VeTek Semiconductor primarius est opificem et supplementum productorum SiC coatingarum in Sinis. VeTek Semiconductoris SiC obductis Epi susceptor industriam summam qualitatem habet, pluribus generibus incrementi fornacis epitaxialis apta est, et operas productos valde nativus praebet. VeTek Semiconductor prospicit ad longum tempus socium tuum in Sinis fieri.

Mitte Inquisitionem

Epitaxia semiconductor ad incrementum tenuis cinematographici cum certis cancellis structurae in superficie materiae subiectae per modos ut gas phase, liquidum tempus vel trabem hypotheticam depositio, ita ut stratum cinematographicum tenue nuper creverit (stratum epitaxiale) habet. eadem vel similis cancelli structurae et propensionis substratae.

technologia epitaxia pendet in fabricandis semiconductoribus, praesertim in praeparatione membranae qualis optimae tenuis, sicut singulae stratae crystallinae, heterostructurae et quantum structurae adhibitae ad altas faciendos machinas fabricandas.

The Epi susceptor key component usus est ut substrata in apparatu incrementi epitaxial sustineat et in epitaxia Siliconis late adhibetur. Qualitas et effectus basi epitaxialis directe afficiunt incrementum qualitatem epitaxialis stratis et partes vitalis agunt in finali machinis semiconductoris effectus.

VeTek Semiconductoriacuit SIC in superficie SGL graphite per methodum CVD coatingit, et epi susceptorem SiC coatingit cum proprietatibus ut resistentia caliditas, resistentia oxidationis, resistentiae corrosionis et uniformitatis scelerisque adeptus est.

![]()

In dolio typico reactor, SiC obducta Epi susceptor dolium structuram habet. Fundum SiC bituminatum Epi susceptore rotali stipite iungitur. Per processum incrementi epitaxialis, alternis horologicis et counterclockwise rotationem conservat. Gas reactionis cameram per colliculum reactionem intrat, ita ut gas fluxus satis uniformem distributionem in camera reactionis format, ac tandem incrementum epitaxiale uniforme efformet.

Necessitudo inter massam mutationem graphite SiC obductis et temporis oxidationis

Eventus studiorum editorum monstrant 1400℃ et 1600℃, massa graphite SiC obductis minime augeri. Hoc est, SiC graphite obductis facultatem antioxidant validam habet. Ergo, SiC obductis Epi susceptor diu in fornacibus maxime epitaxial laborare potest. Si plus requisita aut necessitates nativus habes, pete nobis. optimae qualitati SiC solutiones susceptorum susceptorum Nos committimus providendo SiC.

Basicae physicae proprietates CVD SiC coating

Basicae physicae proprietates CVD SiC coating

Property

Typical Value

Crystal Structure

FCC β Phase polycrystallina, maxime (111) ordinatur

Sic coating densitas

3.21 g/cm³

duritia

MMD Vickers duritiem 500g onus

Frumenti amplitudo

2~10μm

Puritas chemica

99.99995%

Calor Capacitas

640 J·kg-1·K-1

Sublimatio Temperature

2700℃

Flexurae Fortitudo

415 MPa RT 4-punctum

Modulus

430 Gpa 4pt bend, 1300℃

Scelerisque Conductivity

300W·m-1·K-1

Scelerisque Expansion (CTE)

4.5×10-6K-1

VeTek SemiconductorPii Carbide obductis Epi susceptor shops

![]()

![]()